Our Quality Control System

Nine-Step Quality Control Process in Alloy Production:

- Testing of Raw Material's Chemical and Physical Properties

- Experimental Performance Testing of Raw Material Ball Milling

- Sampling and Testing of Physical Properties of Mixed Ball-Milled Materials

- Identification through Sampling and Testing of Physical Properties of Mixed Spray-Milled Materials.

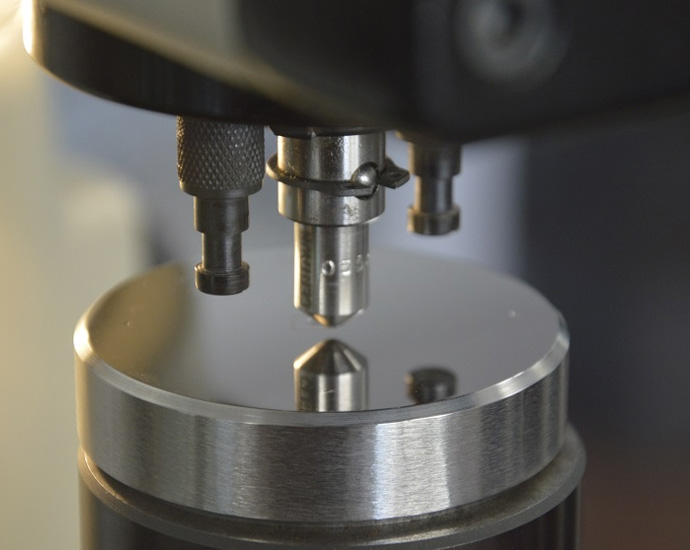

- Initial Performance Testing of Compaction Calibration and Molding

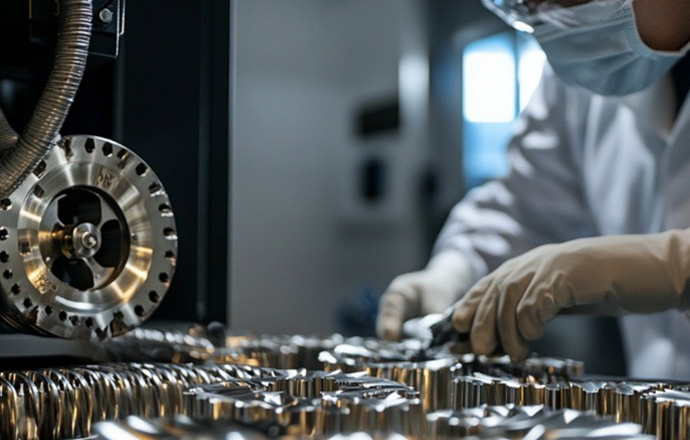

- Self-Inspection of Production Quality during Compaction

- Reinspection of Quality by Compaction Quality Personnel

- Testing of Physical and Mechanical Properties of Sintered Finished Products

- Inspection of Finished Product Models, Dimensions, Appearance, and Defects.